GNova PRESERVING LIQUIDS

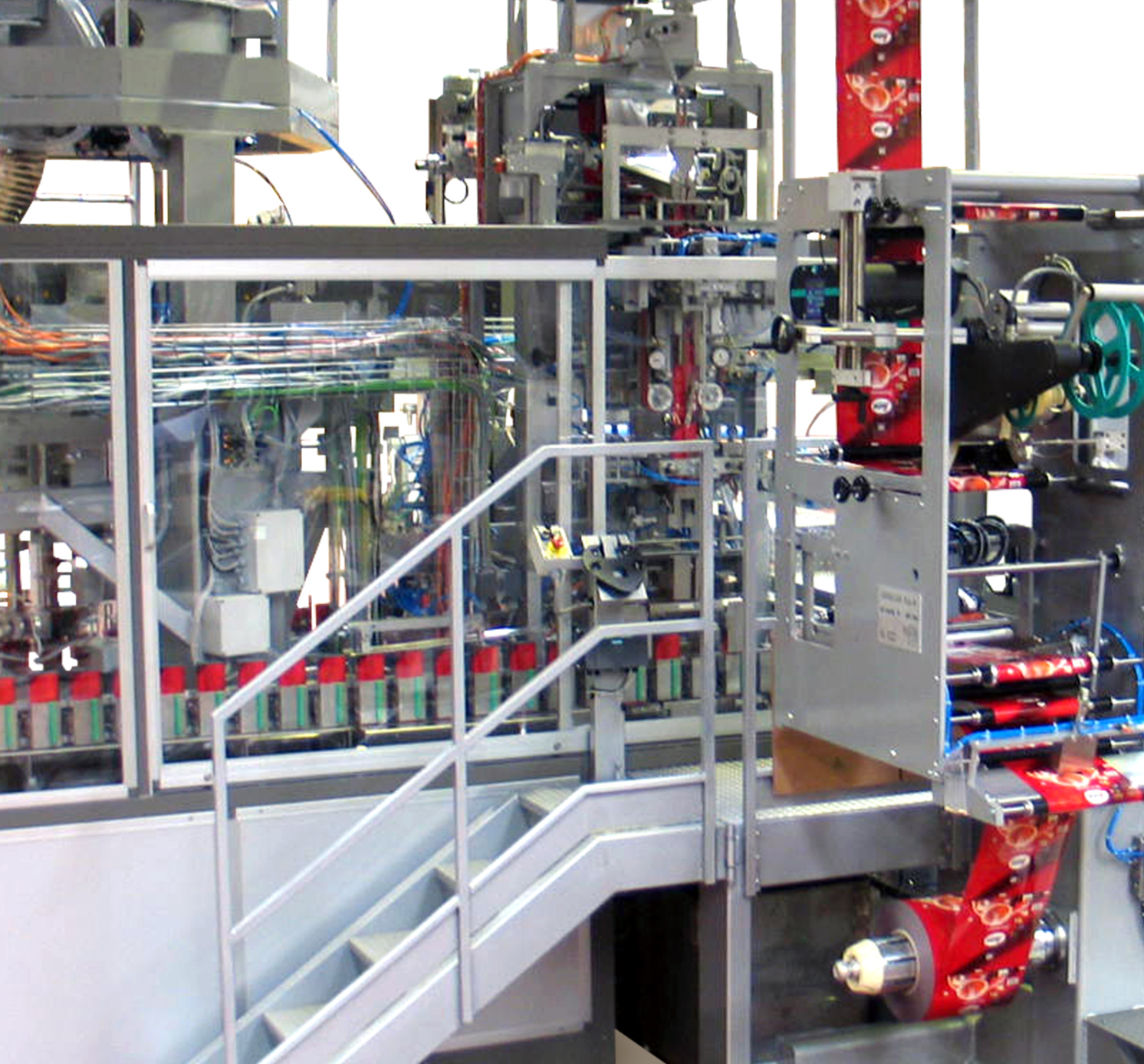

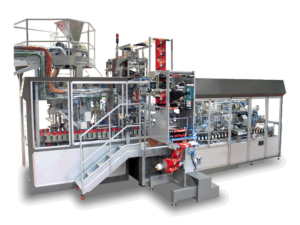

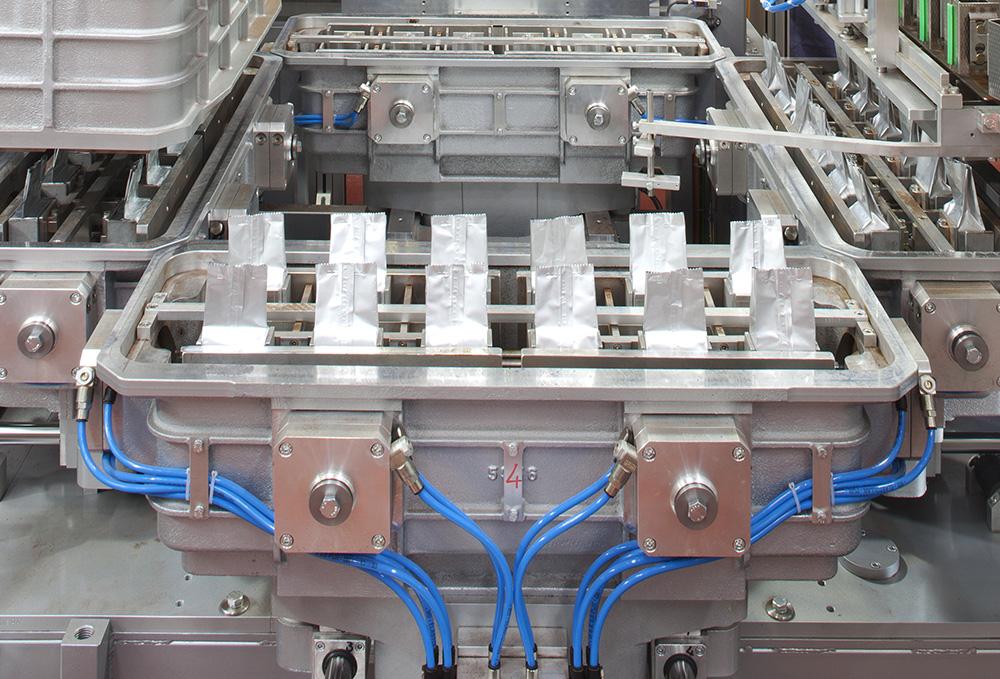

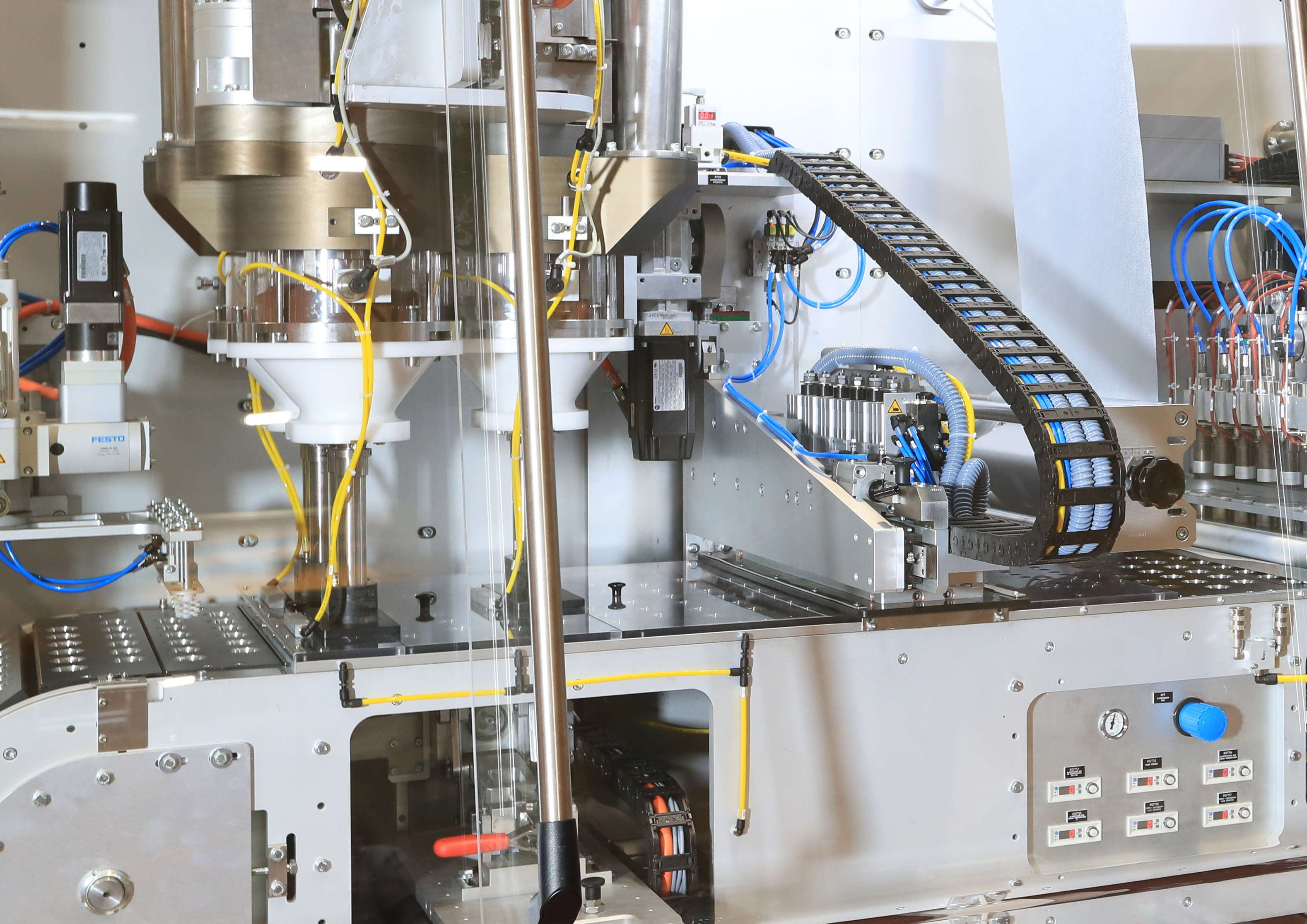

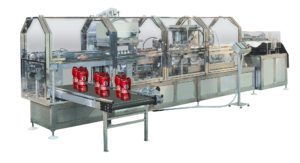

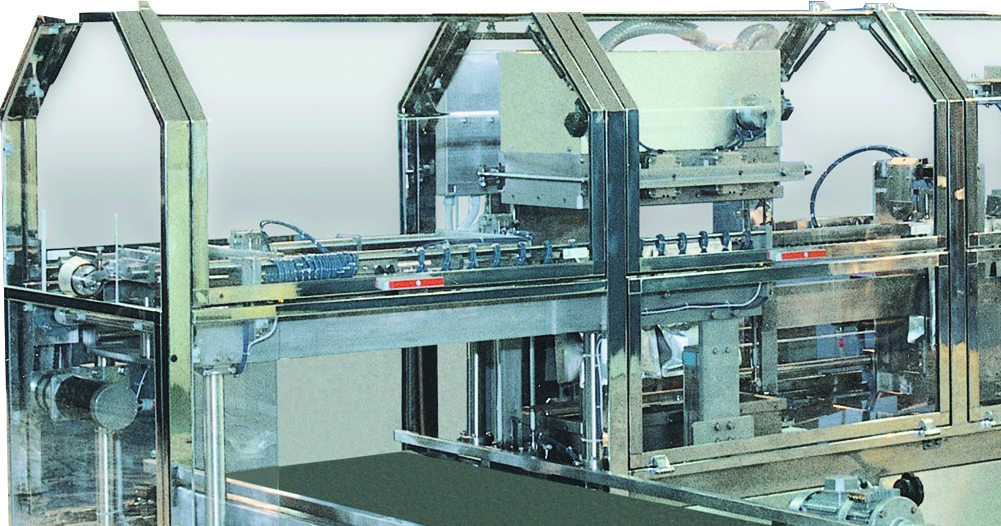

Preserving liquid packaging technology is applied when liquid-solid products require low O2 residual level or thermal post-process to ensure extended shelf life. Two filling stations with proper dosing systems (liquid/solid) are available; blown steam, inert gas mixture and/or head air reduction processes are performed through special presser devices; pouches are eventually closed and sealed.

FILLING OPTIONS

• Insulated or heated tank from 90 up to 300 l

Agitator is also available

• Noozles designed by Goglio:

– 28mm diameter and cut-off for pieces up to 14x14mm for pieces up to 14x14mm

– 50mm diameter for pieces over 14x14mm

– 16mm diameter for particles

• Modified atmosphere

• Optional ultrasonic sealing

SISTEMI DI DOSAGGIO

• Magnetic flow meter suitable for conductive products; mass flow meter for non-conductive

• Pneumatic or motorized (for high density products) volumetric piston filler

• Multihead scales (for solid products)

-

Photogallery

see the photogallery